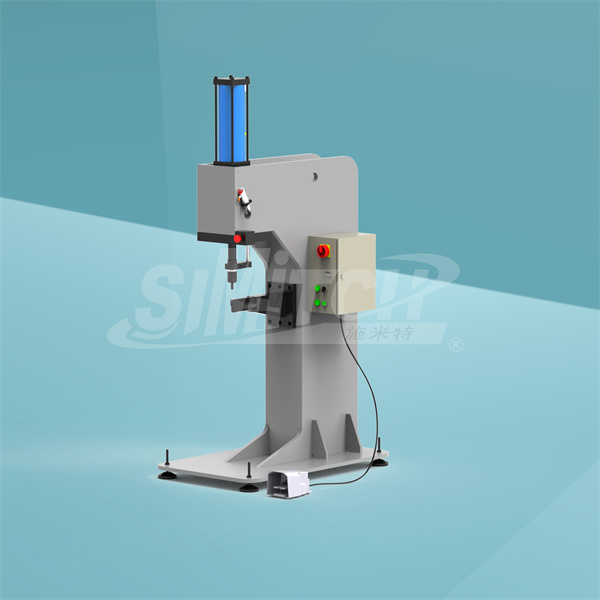

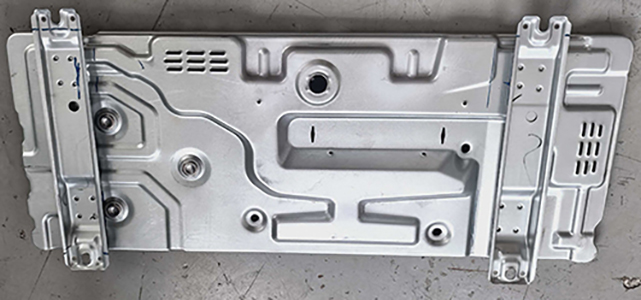

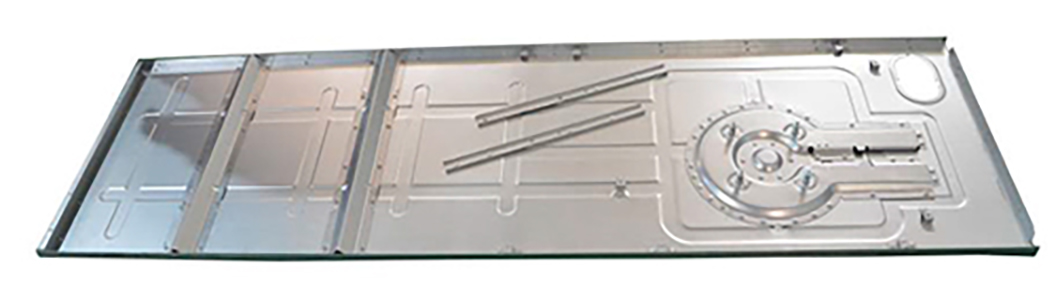

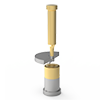

■ Feature: Big throat depth

■ Drive: SIMITCH pneumatic hydraulic BS series cylinder

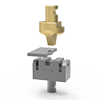

■ Main part:

1. Pneumatic hydraulic cylinder

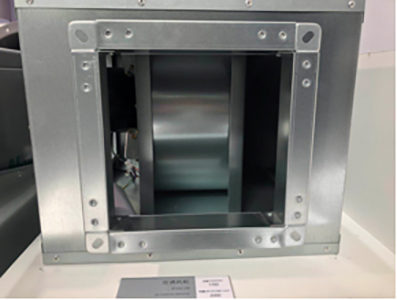

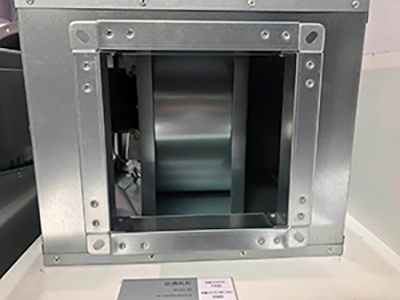

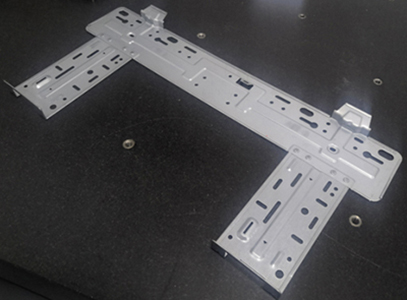

2.CEU machine frame

3.STE safety control system

| Part Number | Max. Capacity | Throat depth | Opening distance | |

| mm | mm | |||

| KN | T | |||

| TCEU 8 | 78 | 7.8 | 400 | 45 |